GREEN BUILDING

Green Building is the practice of creating a built environment, commercial, industrial or residential which is resource efficient in terms of energy, water and materials by reducing building-related impacts on human health and environment throughout the building’s life cycle through better sitting, design, performing certain tests, construction, operation, maintenance, change of use and deconstruction.

We Instruserv by performing certain tests (Air Tightness, Water Tightness, Thermography) to ensure and certify that your building comes under green building category by which you can save a lot of energy consumption and make your area eco-friendly & less energy consumption

We provide cost efficient systems with cent percent quality

ADVANTAGES OF GREEN BUILDING IN MODERN WORLD

IMES follows Regulations based on internationally approved ATTMA, ASTM standards and TARKHEES approved GREEN BUILDING regulation as per government of Dubai- U.A.E for these tests to enhance green building technique

Air Tightness Testing

Air tightness testing is a method of measuring the extent to which air is lost through leaks in the building fabric

Air tightness testing is used to calculate the uncontrolled flow of air through gaps and cracks in the fabric of building (often referred to as infiltration or draughts) and not ventilation, which is the controlled flow of air in and out of the building. Advantages of conducting ATT are improved Energy efficiency, increased Thermal comfort, better Building protection and health of inhabitants.

WHAT IS AIRTIGHTNESS AND WHY

1.Air leaking out of the enclosure causes energy to be consumed when replacement air is conditioned. With information from an air tightness test you can estimate how much air will leak in cold weather versus warm weather, the resulting energy impact can then be estimated for any combination of weather conditions and can inform equipment sizing calculations and computer model predictions of operating energy consumption.

2.You might be able to identify the existence of specific large holes that you may not know about. A blower door test can show where leaks are in the building.

3.Air leaking through the building enclosure feeds condensation – condensation that is hidden within assemblies and causes performance problems.

4.Air leakage can bring polluted outdoor air into a building from, for example, a parking garage, a dumpster, or an exhaust vent. Knowing how much air goes through your building enclosure will help identify how much risk there is of bringing in outdoor pollutants. Once you know, you can set targets to minimize the risk.

We provide Air-Tightness testing facility in all types of enclosed building commercial/residential/industrial ware houses as per customer preferences

Metal Roof Testing

Testing the water penetration of metal roof and sandwich panels to identify the water tightness

Instruserv follows regulations based on internationally approved ATTMA, ASTM standards and TARKHEES regulations of green building for these tests

Water Penetration Test for Windows and Glass Curtains

Water tightness Test for glass windows and panel by using water spray under standard pressure difference.

instruserv follows Regulations based on internationally approved ASTM and TARKHEES Standards for the water penetration test

The most common cause for façade failures is water leakage. To resolve this problem IMES gives an exact and expert solutions.

Cleanroom Testing

To ensure the indoor quality of cleanroom environments like hospitals, pharmaceuticals and electronics assembly industries.

Clean room testing and certification involves checking that it is functioning to the specific parameters and meets the ISO classification.

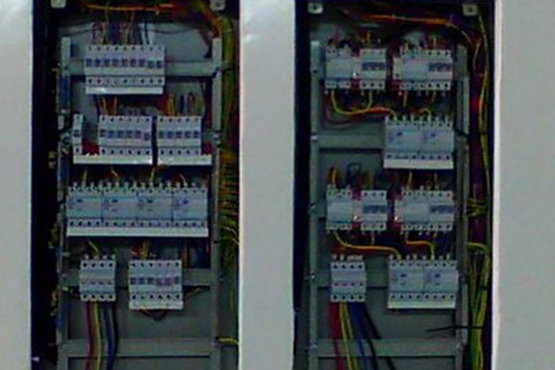

Infrared Thermography Test for Electrical panels

Thermography testing is an examination of electrical components by obtaining a heat distribution image, Instruserv uses Infrared thermography testing technique to identify unbalanced loads, poor connections, deteriorated insulation or any other issues in energized electrical panels or components without dismantling the components